HDPE тръбна машина

QINGDAO COMRISE MACHINERY CO., LTD.

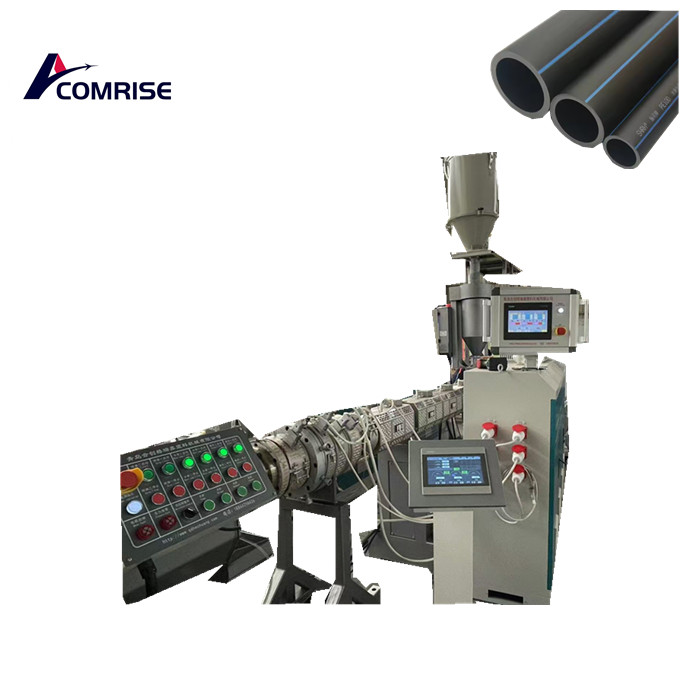

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

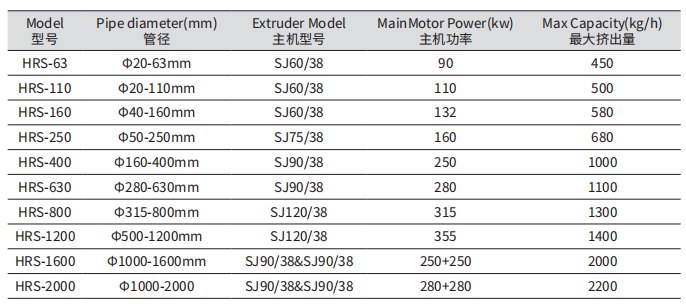

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

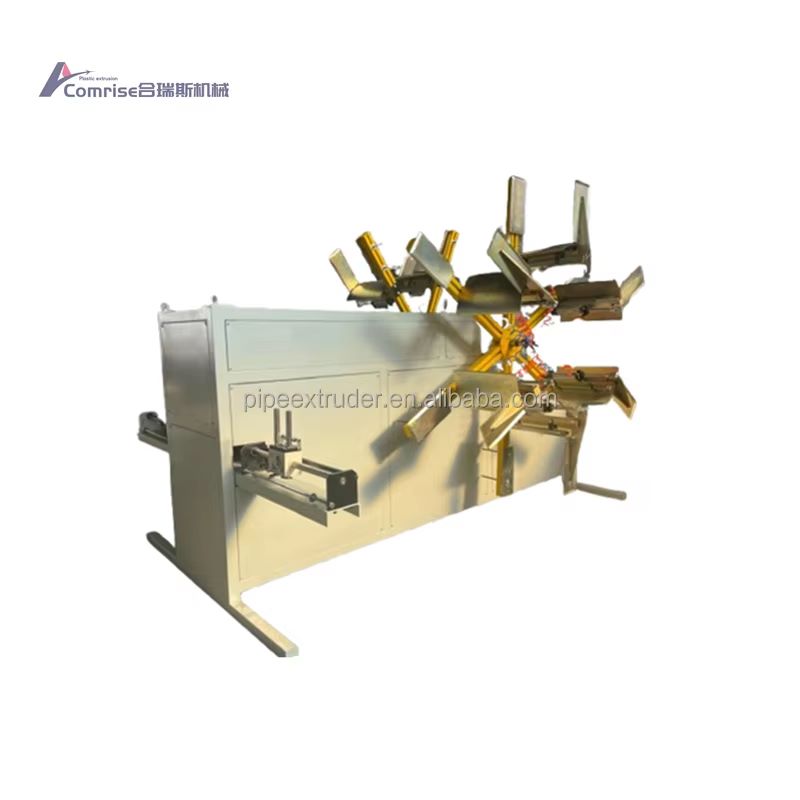

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

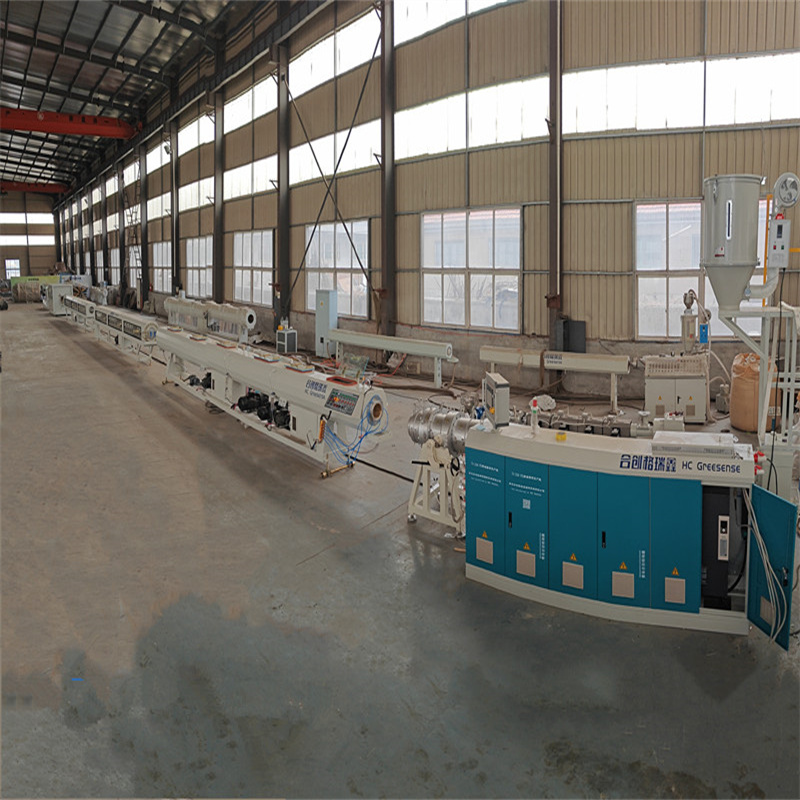

Производствена линия за екструзия на HDPE тръба

Comrise HDPE Производствена машина за производство на тръбопроводи, Китай Топ фабрична пластмасова тръба за производство на тръби, полипропиленова тръба с тази производствена линия на PE, можете да екструдирате висококачествени тръбопроводи за вода и газ с голям диаметър.20 мм-110 мм HDPE Екструзия на тръбата Екструзия Линия

Прочетете ощеИзпратете запитванеМашина за производствена линия на HDPE Pipe Extrusion

Comrise HDPE Pipe Extrusion Machine Machine се прилага главно във вода и газ захранване. Ние сме много професионални доставчици на машини. Тази производствена линия може да произвежда в HDPE тръбата с диаметър 110 мм, 125 мм, 160 мм, 200 мм, 250 и 315 мм, 110-315 мм производствена линия на екструдиране на тръби HDPE, а също така може да бъде подходяща за производство на различни тръби за степен на налягане, вариращи от SDR9-SDR26.

Прочетете ощеИзпратете запитванеABA три слоя Co екструзия HDPE тръбна машина

Comrise Machine China Factory ABA Three Layer Co Extrusion HDPE Pipe Machine е проектиран главно за производство на HDPE/PP тръби, които тръбите се използват главно при напояване, водоснабдяване; Екструдерът може да обработва PP/HDPE гранули (както девствени, така и рециклирани, дори и с композит, изпълнен с тебешир). Изходът на тази машина може да достигне като 150-300 кг/час, той е популярен избор за повечето клиенти.

Прочетете ощеИзпратете запитванеПроизводствена линия на HDPE Pipe Machine

CMRISE Factory HDPE Pipe Machine Production Line приема най -авансовата технология на Европа. Това е ново изследователско постижение на енергийното спестяване на производство Lin, което е подходящо за високоскоростна екструзия на HDPE, PP и други полиолефинови тръби. В сравнение с производствената линия на Cornmon, енергийният ефект достига върху 35%, а ефективността на продукта се увеличава повече от 1 пъти, като по този начин не само спестява разходите за обект и работна ръка, но и подобрява ефективността. 110-135mm HDPE Pipe Machine има приятен външен вид. По -висока автоматична степен, надеждно и стабилно производство е най -добрият доставчик на Китай

Прочетете ощеИзпратете запитванеHDPE ABA CO Extrusion Production Line

Comrise Factory HDPE ABA Co Extrusion Production Line може да се използва за HDPE с голям диаметър газ и PE водни тръби, 110-315mm ABA Co Extrusion производствена линия, с отлична твърдост и гъвкавост, устойчивост на топлината, устойчивост на стареене, висока механична сила, устойчивост на пукнатина на тръбопровода, устойчивост на дефицит на газове, устойчивост на топли, горещи клавиши и т.н. HDPE тръбите с голям диаметър започват да играят много важна роля в градските системи за доставка на вода и газ.

Прочетете ощеИзпратете запитванеHDPE тръбна машина линия

Линията на Comrise Manufact HDPE Pipe Machine е специализирано оборудване, предназначено за производство на полиетиленови тръби. Тези тръби се използват широко в различни приложения, включително водоснабдяване, разпределение на газ, напояване и дренажни системи. 20-50 мм HDPE тръбна машина се състои от няколко ключови компонента, които работят заедно, за да осигурят ефективно и висококачествено производство на тръби

Прочетете ощеИзпратете запитване