Производствена линия на машината с двойна стена, която е

Изпратете запитване

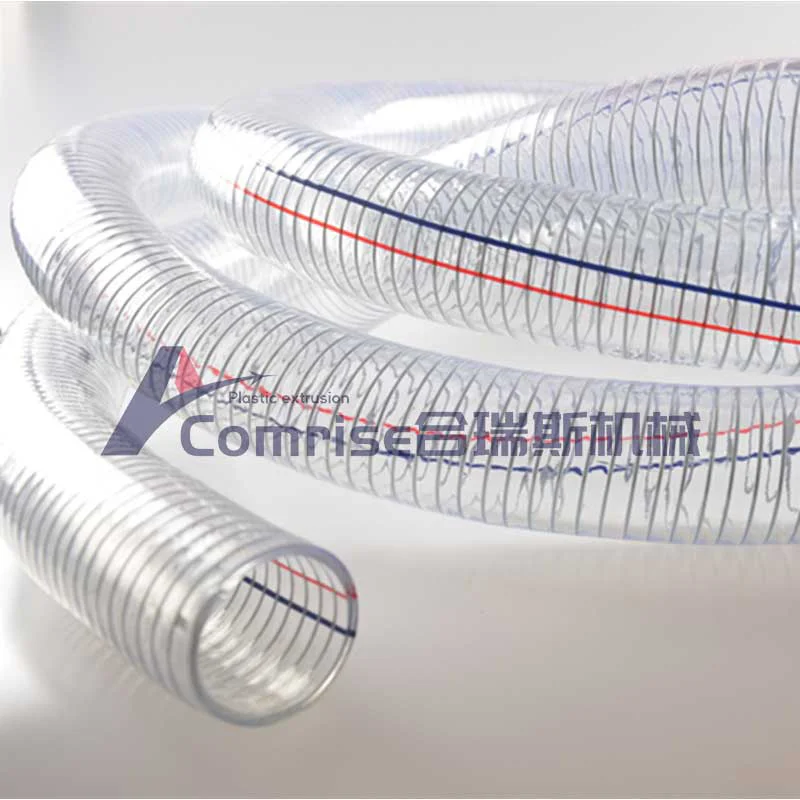

160 мм двойна стена гофрирана тръбна машина Производствена линия пластмаса PE UPVC HDPE Производствени възможности

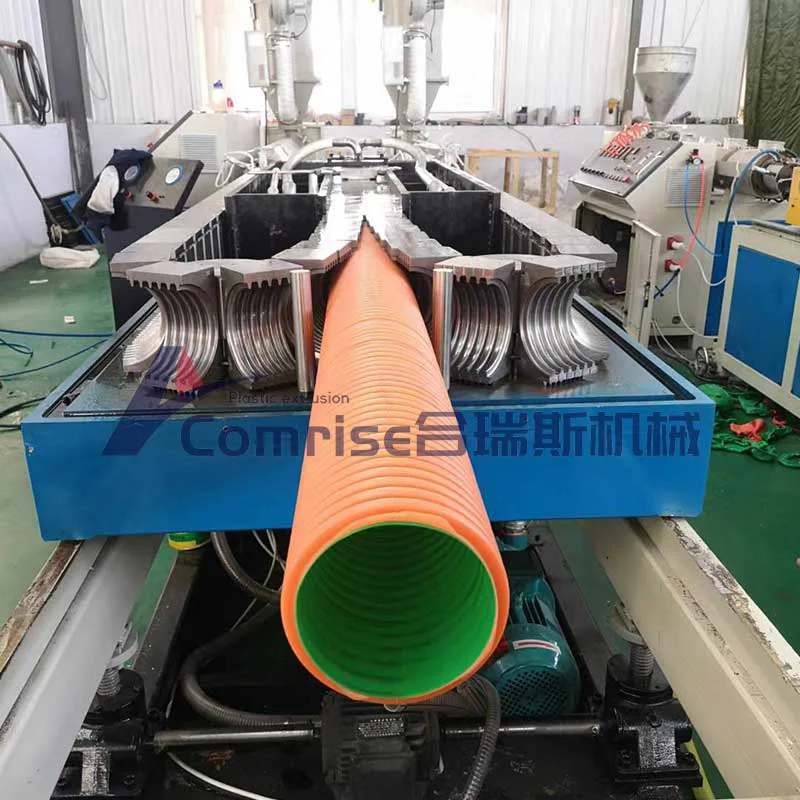

Двойна стена гофрирана тръбна машина Производствена линия произвежда DWC тръба подземен дренаж на канализационната конструкция от двуслойна тръба Екструзия Производствена линия

Алуминиева тръба, образуваща плесен, специализирана в производството на тръби с голям диаметър. Чрез цялостния дизайн на оптимизация на структурата на формата на вълната, той може да постигне перфектна комбинация от висока твърдост на пръстена и ниска скованост на пръстена. Машината за формоване приема мощна система за формоване с водно и охлаждане с въздух, която може да осигури висока точност по време на непрекъснато производство, можем да произвеждаме всички видове

Машината за формоване приема затворена верига модул за формоване, затворен дизайн и прецизно съвпадение на модули и рамки за форми, което прави всяка двойка модули за формоване взаимозаменяеми, вакуумни форми и охлаждане на водата. Рамката на плесен е направена от висококачествена сплав и претърпява обработка на гасене и азот. Рамката и модулът за плесен са прецизно разположени през канали на Dovetail, механично заключени и лесни за промяна на спецификациите. Плъзгащата се част на работната маса е направена от 40Cr, а повърхността се засилва от процеса на йонен азот, така че има дълъг експлоатационен живот.

HDPE/PVC 40-160 мм двойна стена гофрирана тръбна машина

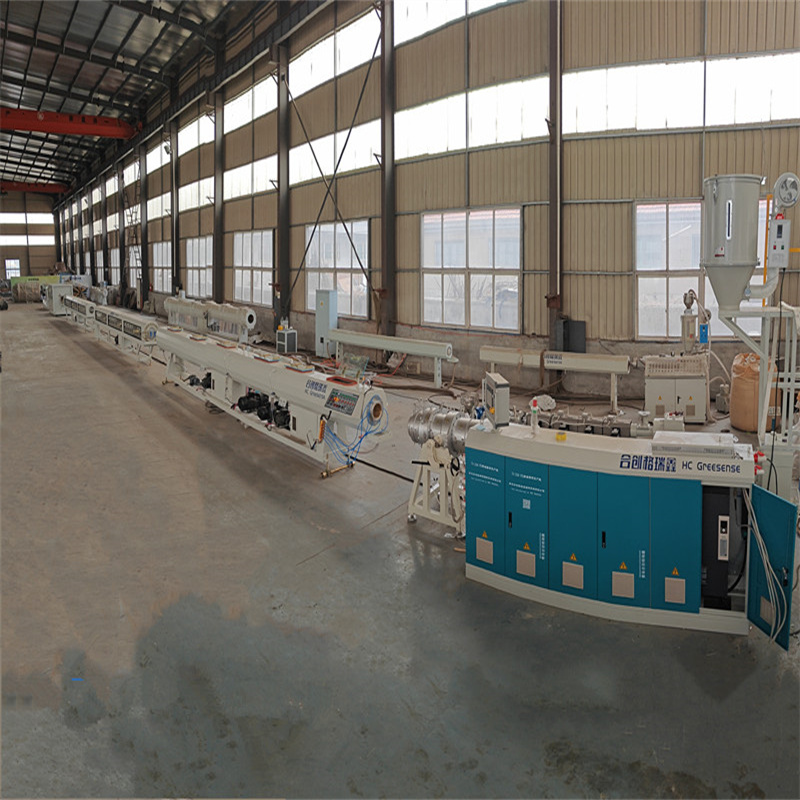

Comrise Double Wall Goruged Pipe Manufacturing Machine е горещ продукт за продажба на нашата компания. Производствената линия с двойна стена е разработена и произведена от Comrise. Той приема дизайн на цикъла на охлаждане на водата на шаблона, използва форми за предаване на предавка, а продуктът приема въздушно охлаждане, за да осигури високоскоростно формоване, равномерни гофри, гладки вътрешни и външни стени и добро положение на линията.

Екструдер с едно винт

Независимо разработеният единичен винтов екструдер на Comrise има висока ефективност на стопилката и непрекъсната стабилност на производството. По -важното е, че ефективните двигатели на предавките осигуряват по -голямо пътуване, по -дълъг живот и по -нисък шум. Единичен винтов екструдер може да се използва за производството на PVC, PE, PP и други материали, тъй като неговата повърхностна азотиране и полиране на обработка разширява експлоатационния живот на винта. Всички тези иновативни дизайни са насочени към осигуряване на по -добро потребителско изживяване на нашите клиенти.

Образуваща машина

1. Двойна стена, гофрирана тръбна машина, ламарината на формиращата машина е лазерна гасена, за да увеличи ефективно своята твърдост и да удължи експлоатационния си живот.

2. Водна охладена и машина за формиране на въздушно охлаждане, което прави формата на гофрираната тръба по-бърза, по-гладка и по-красива.

3. Платформа за формоване с високотемпературен маслен филм може ефективно да предотврати ръждата.

4. Регулиране на формоването на машината: Електрическо управление наляво и надясно, нагоре и надолу.

Вземете оферта сега